5 Essential Simulation Tools for Professional Excellence

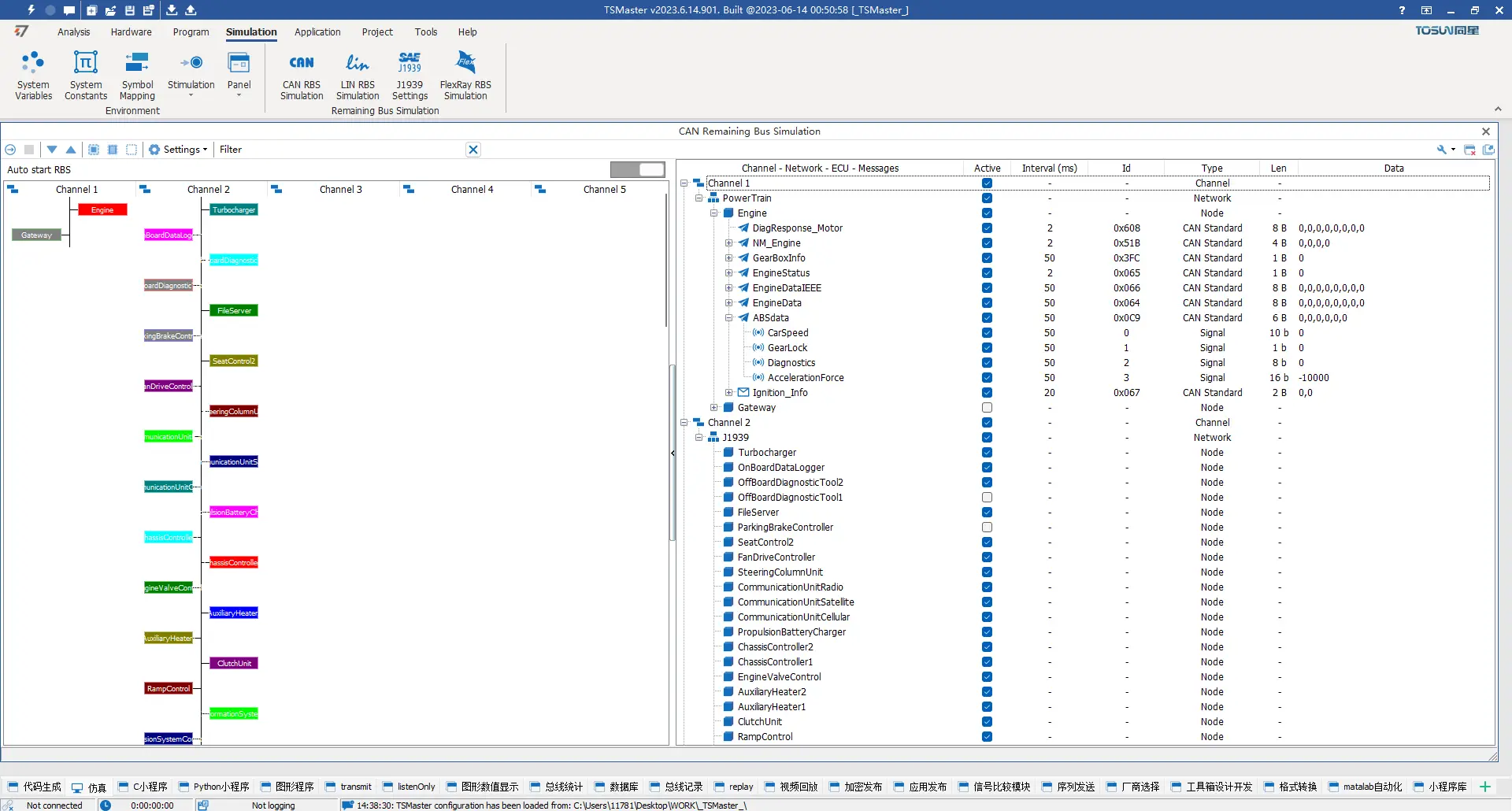

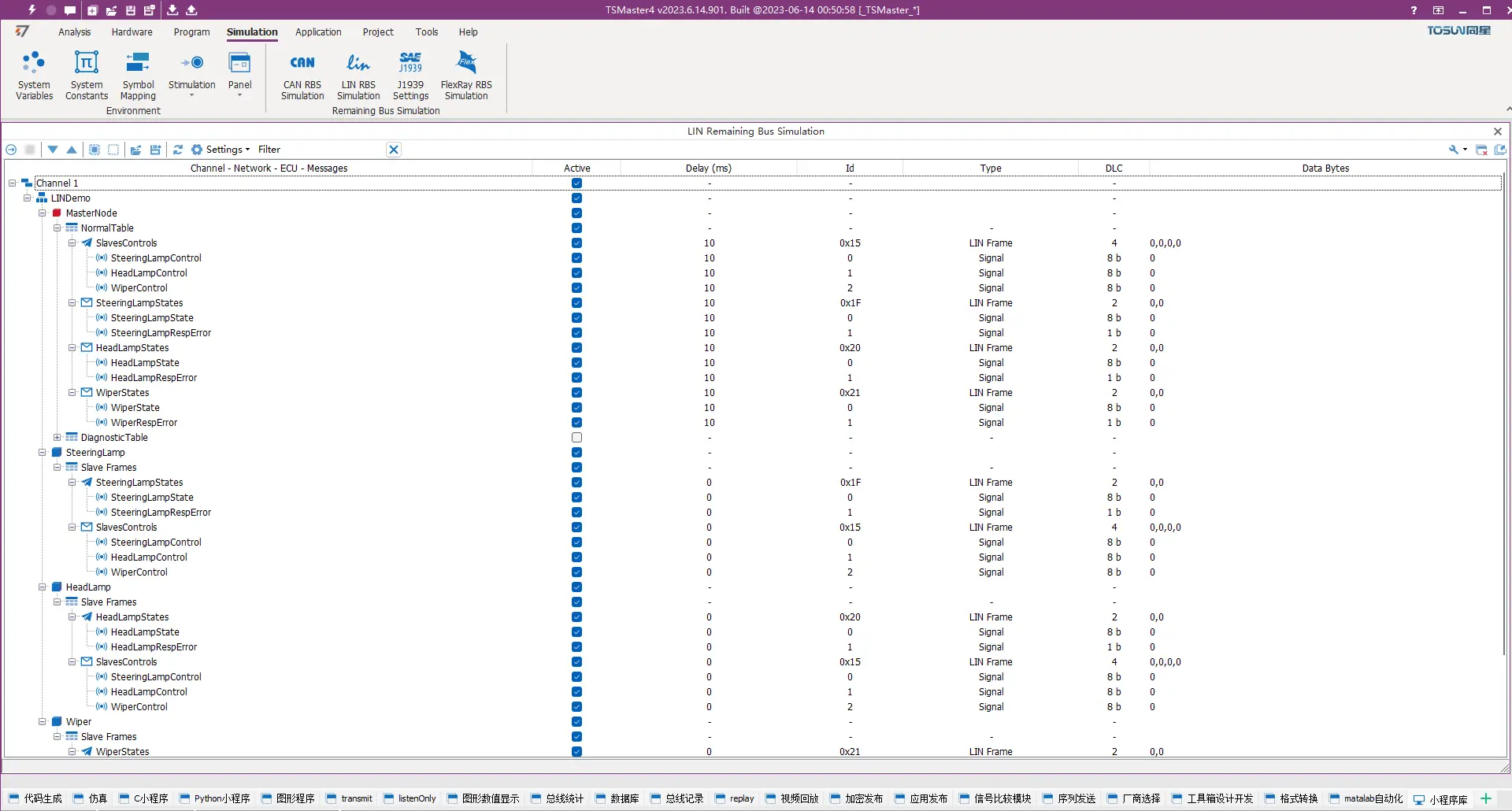

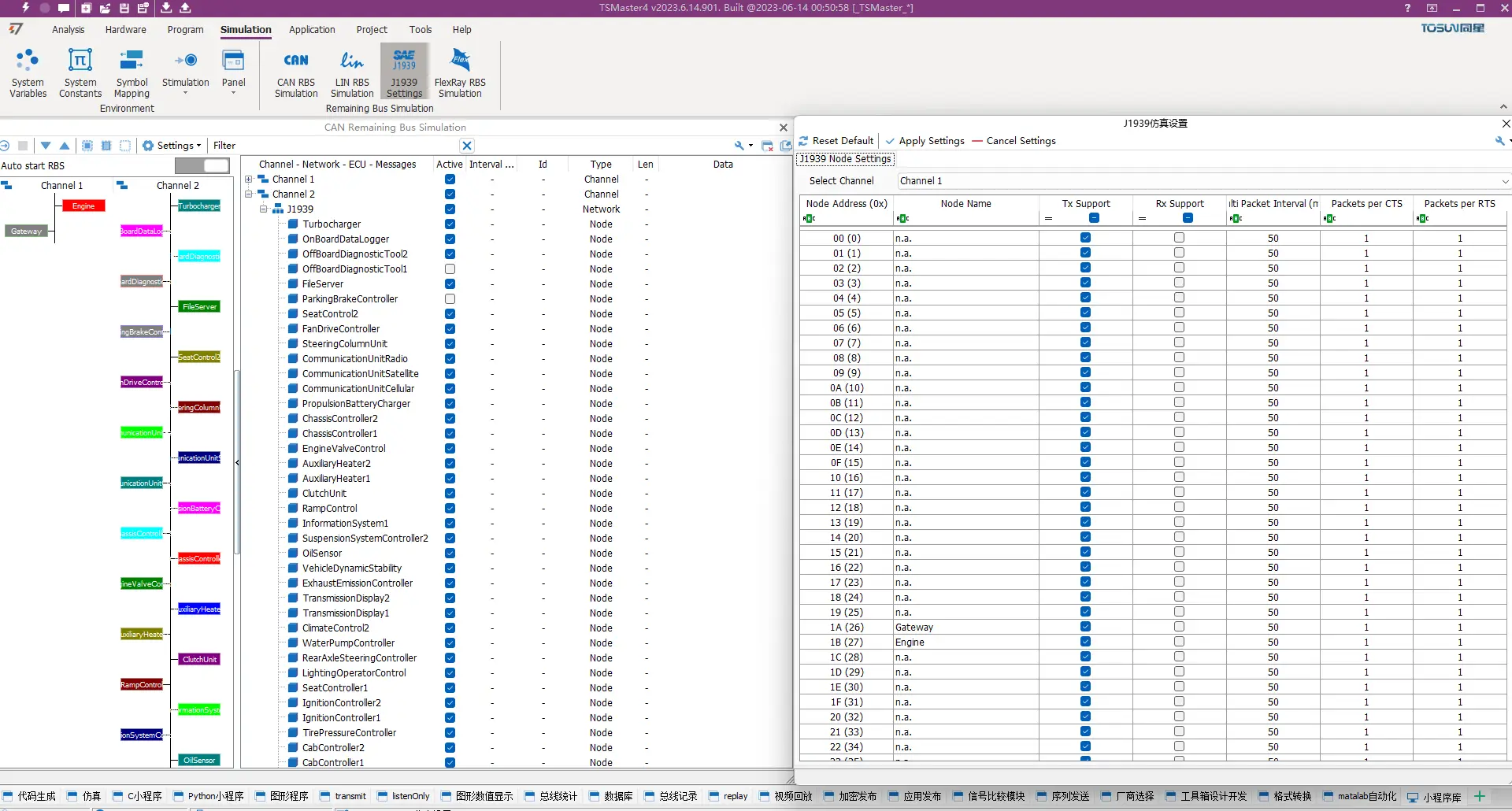

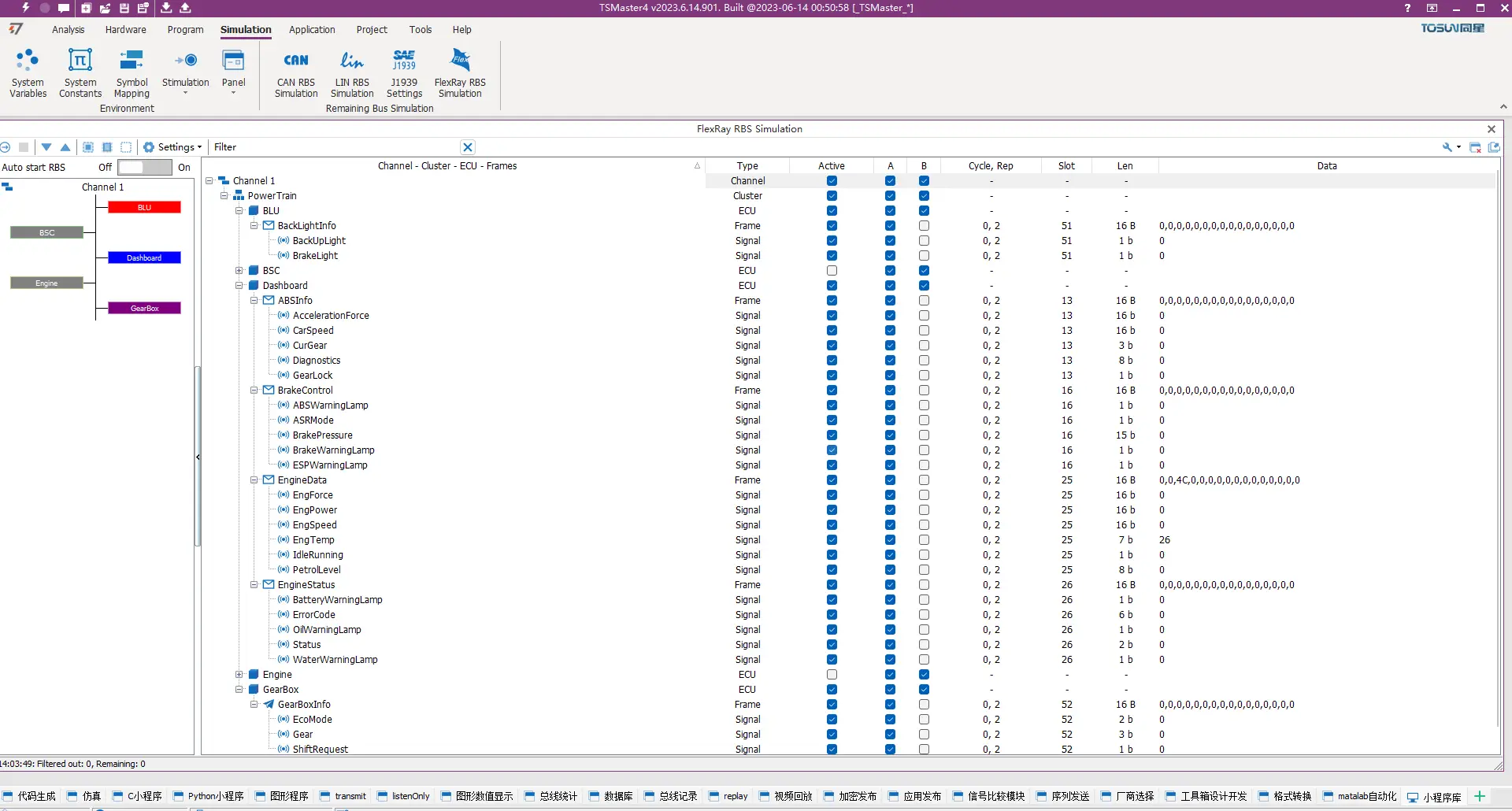

Support CAN, LIN, J1939, FlexRay

C/Python Applet

Mini Program Library

Graphics Panel

Database File Conversion

FAQ

How can I use the FlexRay Bus? (I know it is a broad question, but what hardware is needed to simulate FlexRay Bus communication.)

For using FlexRay bus simulation, you would need to prepare an ARXML file database and a FlexRay device like TC1034.

What types of simulations can TSMaster perform?

TSMaster is equipped with various RBS functionalities, including CAN RBS, CANFD RBS, LIN RBS, FlexRay RBS, Ethernet RBS, and more.

Does TSMaster support co-simulation?

Yes, TSMaster supports co-simulation with CANOe and Matlab Simulink. It enables collaborative testing with Carsim for ECU algorithm simulations involving vehicle dynamics models.

What features does the graphic panel have?

TSMaster’s Panel feature allows you to associate bus signals in the graphic panel for visual representation. When combined with RBS simulation, it also facilitates control over signal and message transmission.

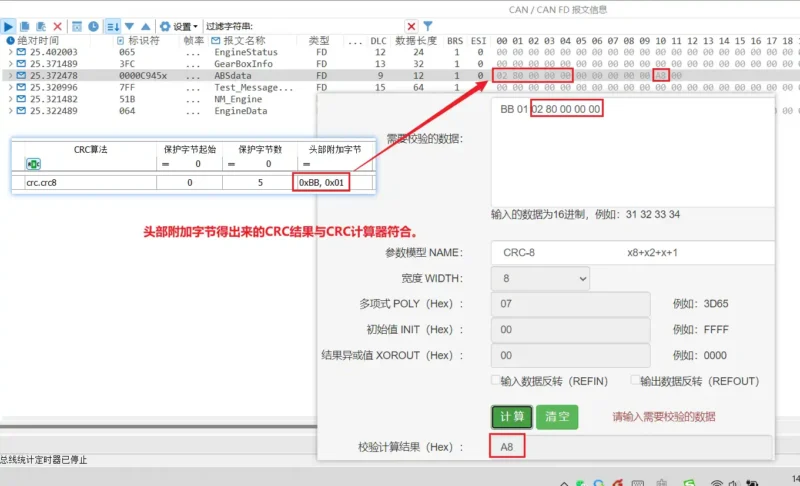

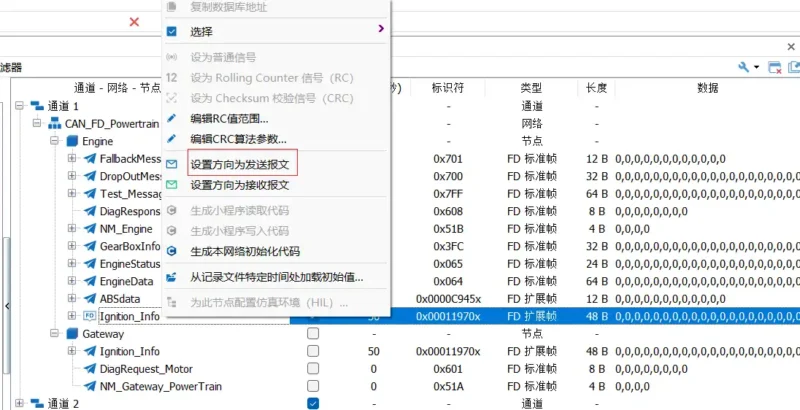

How to use the CRC header attachment byte in CAN RBS simulation?

You can input the header attachment byte, separating multiple bytes with commas. For example, if the original CRC saved bytes are 5, and the data is 0x02 0x80 0x00 0x00 0x00, adding two bytes to the header: 0xBB, 0x01. The actual data for CRC calculation becomes 0xBB, 0x01, 0x02 0x80 0x00 0x00 0x00. By comparing with a CRC calculator, you can verify that the CRC checksum results in A8. We hope this helps you.

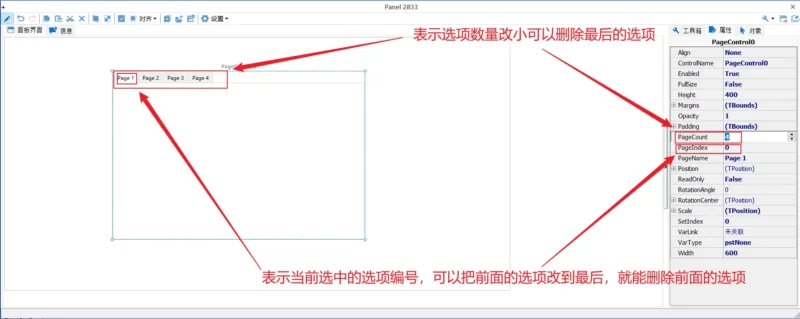

How to delete tabs in the tab control?

To delete tabs in the tab control, you can adjust some properties of the control.

Firstly, the control has a property called ‘PageCount,’ indicating the number of tabs. By reducing this value, you can delete the last few tabs. Additionally, there is a property named ‘PageIndex,’ representing the currently selected tab.

If you need to modify a tab in the middle, you can select that tab, set ‘PageIndex’ to the last tab, and then reduce ‘PageCount.’ I hope this helps you.

How can I add a variable in a graph that represents the difference between two signals?

You can achieve this through signal mapping. Follow these steps:

- Add a new system variable, such as EngSpeed, and set it as an expression.

- Add two independent variables, x1 and x2, binding them to the respective signals.

- In the expression, input x1 – x2, meaning the new system variable EngSpeed will represent the difference between x1 and x2.

Does the signal expression mapping function support offline data mapping?

The current signal expression mapping only supports online data mapping and does not support offline data mapping.

How can I arrange the values in the user variable's value table in sequential order?

The values are sorted alphabetically here. It is recommended to write 1, 2, 3 as 01, 02, 03 to maintain the order of user variable values in the value table. Hope this resolves your issue.

Why does TC1034's FlexRay bus simulation encounter empty frames?

If you encounter problems with empty frames on the FR bus simulation on TC1034, it might be due to interference caused by USB power supply. It is recommended to verify by using another computer.

How to resolve the issue of internal data playback not working during CAN bus simulation with TC1034?

To address this problem, you can consider the following methods:

- Use pure virtual simulation in CAN RBS simulation, utilizing TOSUN’s virtual channel without the need for hardware connection.

- Conduct physical simulation in CAN RBS simulation using TC1034 and the tested device. Simulate by providing ACK responses through the tested device to achieve the desired simulation.

- Enable the Internal Loop feature in CAN RBS simulation on TC1034, utilizing a self-question and self-answer approach. We also offer a firmware upgrade program for version 0428 to enable the internal data replay feature of TC1034.